المنتجات الساخنة

Lime Shaft Kilns ScienceDirect

网页2017年8月1日 More than three quarters of the world’s lime production is high reactive lime. The PFR lime kiln has established itself worldwide for this type of product. This article compares the advantages of modern shaft kilns with other kiln models and explains the

Contact

(PDF) Lime Shaft Kilns ResearchGate

网页2017年8月1日 Lime Shaft Kilns Energy Procedia DOI: CC BY-NC-ND 4.0 Authors: Hannes Piringer Abstract and Figures The annual world lime

Contact

Annular shaft kiln for lime burning with kiln gas recirculation

网页2008年5月1日 The effects of increasing air excess ratio during the process of lime burning in an annular shaft kiln are specifically analysed. The stone presents a case of a

Contact

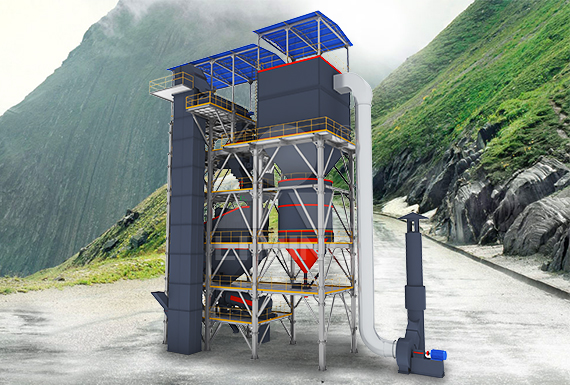

Refratechnik Lime shaft kilns

网页Concepts for shaft kilns. As opposed to rotary kilns, shaft kilns are static production systems in which the raw material (limestone in various particle sizes) is fed into the kiln from the top, from where it moves downwards

Contact

Lime Production an overview ScienceDirect Topics

网页Ranges of efficiency η(%), CO 2 emission factor, daily production and optimal feed grain size for the main kiln types used in the EU-27: Parallel Flow Regenerative Kilns (PFRK),

Contact

Annular shaft kiln for lime burning with kiln gas recirculation

网页2008年5月1日 The effects of increasing air excess ratio during the process of lime burning in an annular shaft kiln are specifically analysed. The stone presents a case of a

Contact

Kiln Types EuLA: European Lime Association

网页Shaft kilns can burn stone from a minimum of 20mm diameter up to 175mm. Some shaft kilns can be operated on natural gas, liquid and solid fuels. This type of kiln tends to produce medium reactivity quicklime, which can then

Contact

(PDF) Lime Shaft Kilns: Modeling and Simulation

网页2013年4月1日 This study presents a mathematical model to predict the heat transfer in a lime kiln. We assume the reaction is not well-stirred. We prove the existence of unique solution of the time-dependent

Contact

Shaft Kiln for Lime Production 911 Metallurgist

网页2019年4月11日 In this case the design that is the subject of this , is known as the ring or annular shaft kiln as developed by Mr. Karl Beckenbach of West Germany. It is a single vertical cylinder to which are

Contact

Lime kilns Cimprogetti

网页2023年5月15日 The Twin Shaft Regenerative (TSR) kiln family consists of two main groups: Direct Crossover featuring a single channel placed between the shafts, Radial Crossover featuring circular channels around

Contact

Annular shaft kiln for lime burning with kiln gas recirculation

网页2008年5月1日 Lime production represents the second largest contributor to industrial CO 2 emission in China, but it has not been well addressed. Herein, an efficient and environment-friendly Limestone Calcination Process with CO 2 Looping and Recovery (LCPCLR) is established to solve the associated environment issue. CO 2 serves as heat carrier in the

Contact

China Shaft Kiln, Shaft Kiln Manufacturers, Suppliers, Price

网页China Shaft Kiln manufacturers Select 2023 high quality Shaft Kiln products in best price from certified Chinese Rolling Machine, Chemical Equipment suppliers, wholesalers and factory on Made-in-China Low Cost Vertical Shaft Lime Kiln for Limestone Production Line . US$ 100000 / Piece. 1 Piece (MOQ)

Contact

Energy and exergy assessments of a lime shaft kiln

网页2013年3月1日 Introduction. Lime production is an energy intensive process characterized by high emissions of CO 2. The main energy consumption of lime production is located in the calcination process and accounts for more than 90% of the total energy consumption [1]. The fuel consumed during calcination represents ca. 50% of the production costs of lime [2].

Contact

Numerical analysis of the novel lime calcination process for

网页2021年3月22日 Lime is an important industrial raw material widely used in iron- and steel-making, flue gas desulfurization, construction, and making industries. Lime is generally obtained via calcining limestone in a kiln, i.e., limestone is heated and decomposed to generate lime and carbon dioxide (CO 2 ). In the conventional lime calcination, the

Contact

Lime Shaft Kiln for Sale, Energy-efficient Vertical Lime Kiln

网页New type TTHN vertical shaft kiln for lime production. Output 100-500t/d, particle size 30-60/40-80mm. Lime shaft kiln with reasonable design and excellent performance for sale.

Contact

(PDF) Lime Shaft Kilns ResearchGate

网页2017年8月1日 A shaft kiln (diameter 4 m and height 21 m) for processing lime is investigated [5]. To present a 1D mathematical model to simulate the lime-burning process in normal shaft kilns [6], Gutiérrez

Contact

Annular shaft kiln for lime burning with kiln gas recirculation

网页2008年5月1日 For the conventional calcination process widely used in lime production, as shown in Figure 1a, because of the fuel combustion in the kiln, the above two parts of CO 2 are emitted as flue gas

Contact

Lime Production: Industry Profile US EPA

网页2015年9月1日 EPA Contract Number RTI Project Number 68-D-99-024 7647-001-020 Lime Production: Industry Profile Final Report September 2000 Prepared for Eric L. Crump

Contact

Refractories for Lime Calcination SpringerLink

网页2020年11月29日 5.3.2 Twin Shaft Kiln. These are also called Parallel Flow Regenerative (PFR) kiln because the burden and the hot combustion gas flow in the same direction. In this process, the peak temperature of calcinations remains low enough not to allow the CaO crystallites to get fused, and the product obtained has high reactivity and suitable for

Contact

11.17 Lime Manufacturing US EPA

网页2015年9月10日 The heart of a lime plant is the kiln. The prevalent type of kiln is the rotary kiln, accounting for about 90 percent of all lime production in the United States. This kiln is a long, cylindrical, slightly inclined, refractory-lined furnace, through which the limestone and hot combustion gases pass countercurrently. Coal,

Contact

Process Simulation of Lime Calcination in Mixed Feed

网页2014年2月18日 Mixed feed shaft kilns are widely used throughout the world in the industries using both lime and carbonation gas, such as soda ash, gold and magnesia industries. This work aims to improve the mixed feed lime kiln operation through a better un-derstanding of the process. The work focuses on development of a mathematical model

Contact

11.17 Lime Manufacturing U.S. Environmental

网页2021年6月25日 The heart of a lime plant is the kiln. The prevalent type of kiln is the rotary kiln, accounting for about 90 percent of all lime production in the United States. This kiln is a long, cylindrical, slightly inclined, refractory-lined furnace, through which the limestone and hot combustion gases pass countercurrently. Coal,

Contact

Lime kilns Cimprogetti

网页2023年5月15日 ABC ® (Advance Burning Concept) is the Cimprogetti vertical single shaft kiln with counter current flow arrangement and is the latest in the evolution of compact design.. Thanks to its particular firing

Contact

Novel Lime Calcination System for CO2 Capture and Its

网页2020年10月10日 1. Introduction. Lime is an important industrial raw material and is widely used in major industries such as iron- and steel-making, flue gas desulfurization, construction, and -making industries. 1−3 Lime is generally obtained by thermal decomposition of limestone into quicklime and carbon dioxide (CO 2) in a shaft kiln 4 or a

Contact

Shaft Kiln_Shaft Kiln 10% Energy-saving for Lime Production

网页As an experienced lime kiln manufacturer, we offer shaft kiln for lime production lines, the lime shaft kiln is the most efficientecological way to calcine limestone for lime production. 10% energy-saving, 20% yield improvement. Processing Capacity: 50-400t/d. Max. Feeding Size:30-120mm. Application Fields: Vertical shaft kiln is suitable

Contact

Emission Factor Documentation for AP-42 Lime

网页2021年6月25日 The heart of a lime plant is the kiln. The prevalent type of kiln is the rotary kiln, accounting for about 90 percent of all lime production in the United States. This kiln is a long, cylindrical, slightly inclined, refractory-lined furnace through which the limestone and hot combustion gases pass countercurrently.

Contact

Shaft Kiln for Lime Production 911 Metallurgist

网页2019年4月11日 Shaft Kiln for Lime Production. New is a relative term, and when used with reference to a concept as old as shaft kilns can be applied to a number of designs. In this case the design that is the subject of this

Contact

Shaft kiln utilized for lime production PREDESCU; LUCIAN A.

网页Shaft kiln utilized for lime production . United States Patent 4747773 . Abstract: A vertical shaft kiln utilized in calcining limestone defines a series of processing zones including an upper preheating zone, a first calcining zone, a second calcining zone having a length twice that of the first calcining zone and a material cooling zone

Contact

Lime Production Technology Lime Production Process_Cement Production

网页2018年6月17日 Such as soil kiln, ordinary shaft furnace type, rotary kiln and so on. The conventional shaft furnace type kiln, in which the earth kiln and the use of coal as the calcined fuel, is a phase-out equipment. Most of the furnaces used today are gas-fired shaft furnaces and rotary kilns. Ordinary gas-fired shaft furnace type lime kiln is divided

Contact

Lime Shaft Kilns ResearchGate

网页The annual world lime production amounts to approximately 350 million tons. The most efficient and ecological way to calcine limestone and dolomite is the use of modern shaft kilns.

Contact