المنتجات الساخنة

Wet and dry grinding of coal in a laboratory-scale ball mill:

网页2020年1月1日 Grinding test were performed in an XMQ-Φ240 × 90 laboratory-scale

Contact

Ball mill abrasion test (BMAT): Method development and

网页2022年1月1日 The ball mill abrasion test (BMAT) is an industrially-relevant multipurpose

Contact

Exploring ball size distribution in coal grinding mills

网页2014年5月1日 Introduction The expected grinding performance of a mill can be

Contact

Analysis of ball mill grinding operation using mill power specific

网页2014年3月1日 Analysis of a large amount of batch ball mill grinding data available in the

Contact

Ball mill characteristics and test conditions Mill

网页Grinding tests were conducted using a pear-shaped ball mill on an oxidized copper-cobalt ore to determine the milling parameters. Twelve mono-sized fractions of the ore sample were prepared and

Contact

Exploring ball size distribution in coal grinding mills

网页2014年5月1日 1. Introduction. The expected grinding performance of a mill can be

Contact

(PDF) Grinding in Ball Mills: Modeling and Process

网页2012年6月1日 A ball mill is a type of grinder widely utilized in the process of mechanochemical catalytic degradation. It consists of one or more rotating cylinders partially filled with grinding...

Contact

Ball Mill Grinding Theory Crushing

网页2017年4月28日 Testing Plant Equipment: In order to determine, among other things, the operating conditions of the ball-mill when working on this rock, a test mill of about 300 T. daily capacity was erected at Duluth,

Contact

Standard Bond Ball Mill Grindability Test Method-Procedure

网页2015年12月14日 Standard Bond Ball Mill Grindability Test Method-Procedure. Here is

Contact

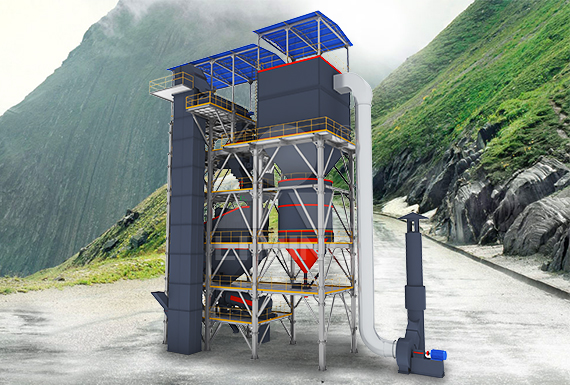

Coal Ball Mill Grinding for Different Kinds of

网页Coal Ball Mill Details. Coal ball mill is the main equipment for grinding pulverized coal. The raw material of coal powder is coal with various hardness, and it drying in the coal mill grinding process to obtain finished

Contact

Coal Ball Mill Grinding for Different Kinds of

网页Coal Ball Mill. Feeding size: ≤25mm. Capacity: 5-20t/h. Functional advantages: Less failure and reliable operation. Applications: It is mainly used for grinding coal of various hardnesses, and is also suitable for coal

Contact

Ball Mill an overview ScienceDirect Topics

网页8.3.2.2 Ball mills. The ball mill is a tumbling mill that uses steel balls as the grinding media. The length of the cylindrical shell is usually 1–1.5 times the shell diameter (Figure 8.11 ). The feed can be dry, with less than 3% moisture to minimize ball coating, or slurry containing 20–40% water by weight.

Contact

Grinding balls, buy metal balls from Metinvest

网页Purchase. Metinvest offers grinding balls for ball mills with diameters from 30 to 120 mm of 1-4 hardness groups for the mining, coal, construction (cement manufacturing) and other industries. Steel balls can be

Contact

Vertical Coal Mill for Coal Grinding in Cement

网页Vertical Coal Mill. Feeding size: ≤110mm. Capacity: 5-70t/h. Motor power: 110-1400kW. Applications: Vertical coal mill is mainly used for grinding raw coal, bituminous coal, and other fuels into coal powder, which is supplied

Contact

Ball Mills 911 Metallurgist

网页2017年2月13日 CERAMIC LINED BALL MILL. Ball Mills can be supplied with either ceramic or rubber linings for wet or dry grinding, for continuous or batch type operation, in sizes from 15″ x 21″ to 8′ x 12′. High density

Contact

EFFECT OF BALL SIZE DISTRIBUTION ON MILLING

网页2021年7月31日 size on milling rate for a South African coal. A series of batch grinding tests were carried out using three loads of single size media, i.e. 30.6 mm, 38.8 mm, and 49.2 mm. 5.2.2 Original equipment manufacturer recommended ball size distribution 64 2.1 Breakage mechanisms in a ball mill 22

Contact

Exploring ball size distribution in coal grinding mills

网页2014年5月1日 The ball size distribution (BSD) in a mill is usually not known, as the measurement of the charge size distribution requires dumping the load and laboriously grading the balls into size classes. Fortunately we had one set of data as discussed below. The general non-availability of BSD necessitates the use of ball wear theory to estimate

Contact

Coal Pulverizer Power Plant Pall Corporation

网页1 天前 The four most common coal pulverizers types are: Ball-Tube Mills. This type of mill consists of a rotating tube filled with cast alloy balls. Coal is introduced through two hollow trunnions on each side of the tube. As the

Contact

Size Reduction and Energy Requirement ScienceDirect

网页2016年1月1日 A Bond ball mill work index is then performed on the mill product for the design of SAG-ball mill circuits. This is important because it was found that there was a 1–1.5 kWh/t higher ball mill work index if the –3.35 mm ball mill test feed size is obtained by SAG mill grinding compared with crushing.

Contact

en/cement factory coal mill system test.md at main lbsid/en

网页Roller Mill For Cement Factory Production capacity : 0.615t h Feeding Size : ≤25mm Discharging Size : 0.0.89mm Ball mill is also known as ball grinding mill.Ball mill is the key equipment for recrushing after the crushing of the materials.It is widely usedMisr Beni Suef Cement Company postpones coal mill Misr Beni Suef Cement Company has

Contact

(PDF) Grinding in Ball Mills: Modeling and Process

网页2012年6月1日 A ball mill is a type of grinder widely utilized in the process of mechanochemical catalytic degradation. It consists of one or more rotating cylinders partially filled with grinding balls (made

Contact

Ball mill, Ball grinding mill All industrial

网页ball grinding mill L14 series. with rods horizontal stone. Rotational speed: 42 rpm 69 rpm. Rod / Ball Mills are Rubber coated and manufactured in Double and Triple Roll models. The Rolls are 120 mm diameter x 1200

Contact

Ball mill characteristics and test conditions Mill

网页The ball mill was run for seven time intervals, ranging from 0.5 to 30 min. This study investigated ultra-fine coal grinding performance of four low- to moderate-cost grinding media in a

Contact

Types of Ball Mill Machine Meet Your Industrial

网页Ball Mill Principle. The ball mill machine is mainly composed of cylindrical cylinder, end cover, bearing and big gear ring. Cylinder: The cylinder is filled with a ball mill grinding media (steel balls or steel cylpebs) with a

Contact

Ball Mill Ball Mills WetDry Grinding DOVE

网页1 天前 DOVE small Ball Mills designed for laboratories ball milling process are supplied in 4 models, capacity range of (200g/h-1000 g/h). For small to large scale operations, DOVE Ball Mills are supplied in 17 models,

Contact

Coal Mill in Cement Plant Vertical Roller MillAir-Swept Ball Mill

网页It is a mechanical device used to grind raw coal into pulverized coal powders. The most used coal mills in cement plants are air-swept ball mills and vertical roller mills. At present, most cement plants use coal as the main fuel in the clinker production process. The standard coal consumed by the new dry process for producing 1 ton of cement

Contact

Analysis of noise and vibration during the operation of the ball mill

网页Analysis of noise and vibration during the operation of the ball mill The ball mill is used for grinding materials after crushing, and CHAENG is a professional manufacturer of ball mill accessories, such as girth gear of ball mill, ball mill trunnion, ball mill end cover, etc., which are used by customers in various industrial fields. Ball mills are widely used in industries

Contact

Review on vertical roller mill in cement industryits

网页2021年1月1日 The grinding process in ball mills and vertical roller mills is fundamentally different [15]. Following are advantages of VRM over Ball Mills with reference to these issues: • Strong drying ability Inlet hot air from Kiln can dry materials with 20% water content. (max moisture 20% vs. 3% in ball mill) [15], [16]. •

Contact

Grinding Ball WearBreakage by Impact

网页2017年10月18日 There is a wide variation in the impact and abrasion properties among different lots and makes of 75-mm commercial grinding balls, according to laboratory tests. The mean impact lives to breakage

Contact